As the grade is getting more and more involved in industry 4.0. It is understood that customers are also expecting to transform their operations, yielding higher productivity and competitiveness. Strategically armed with OPC (Optimum-Paste Control). G-Titan makes your journey towards Lights - out manufacturing a seamless one.

Complemented with QPC (Quality Print Control), G-Titan stands firmly with the belief that nothing is more important than a good print. These revolutionary changes of the fundamental aspects of SMT printers, will bring about a kind of efficiency that you've never had.

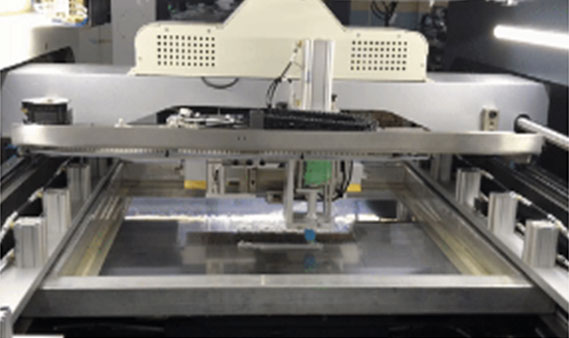

Standard Features & Performance

Optimum Paste Control (OPC) - Get Ready For Lights - Out Manufacturing

Auto Paste Dispensing

The paste is automatically dispensed across the entire squeegee length, maintaining at 15mm rolling diameter, adopting the common 500 gram's solder paste jar. completely eliminates the wastage of solder paste overflowing to the sides of squeegee.

Paste Rolling Diameter Monitoring System

Tracing solder paste rolling diameter in real time and trigger the auto dispensing if it falls below 10mm. Completely eliminate insufficient solder paste on stencil and keep the paste rolling speed within optimum range to achieve best printing result.

OPC Squeegee

Retainers at both sides can be adjusted to the exact length of the PCB, enabling solder paste to be retained within the PCB length to obtain a clean sweep. Possess absolute control over desired printing area, to achieve best printing quality.

Optimum Quality Print Control (QPC) - Nothing Is More Important Than A Good Print

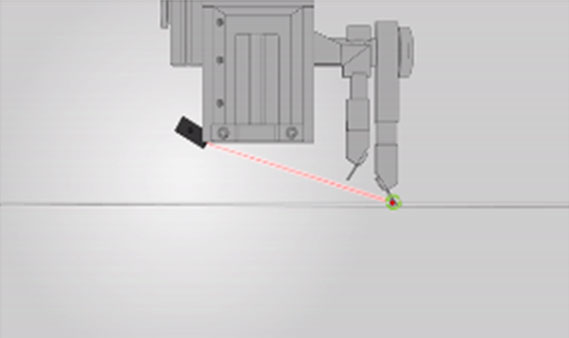

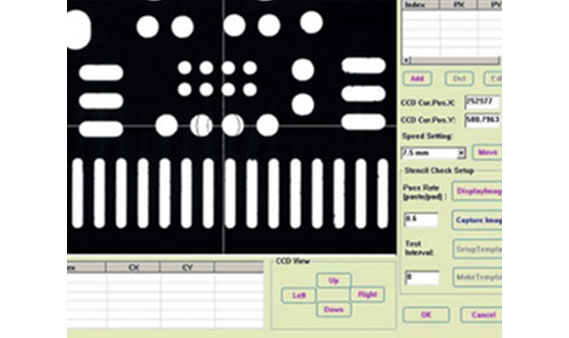

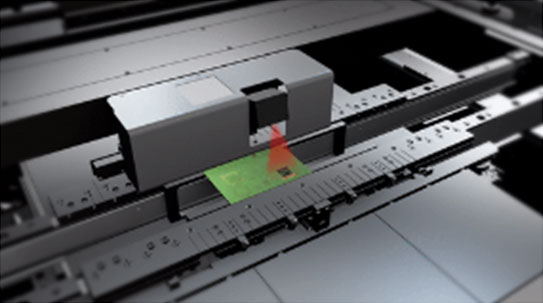

Stencil Aperture Inspection System

The Using panel light installed at the top and CCD camera below to inspect the clogging of stencil aperture to eliminates poor quality stencil being used, ensure quality printing right from the start.

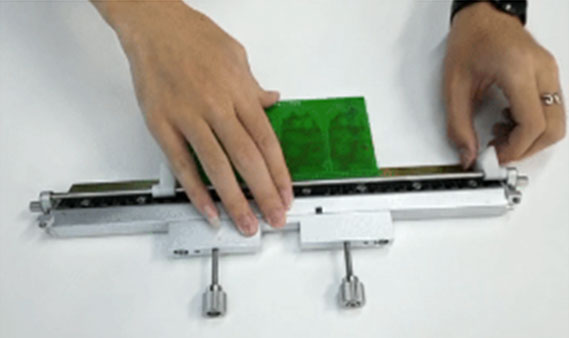

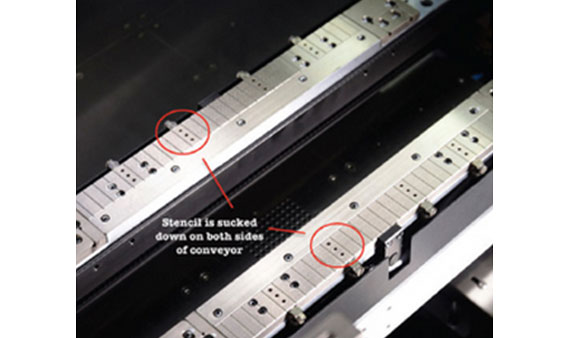

The Stencil Lock & PCB Clamper

Tracing solder paste rolling diameter in real time and trigger the auto dispensing if it falls below 10mm. Completely eliminate insufficient solder paste on stencil and keep the paste rolling speed within optimum range to achieve best printing result.

Options

Ready for Industry 4.0

Through machine status, parameters can be uploaded automatically. Designed to support customer's advancement towards industry 4.0 intelligence connection with user's MES system, enhancing product traceability and maintenance needs.

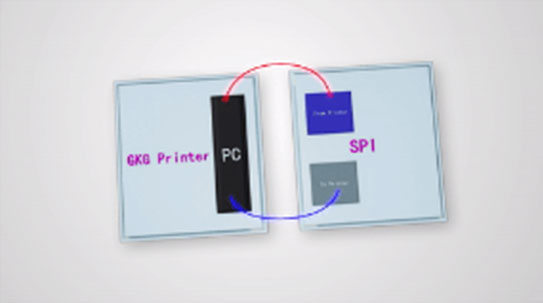

SPI Close loop Connection

Tracing With SPI close-loop system, machine will automatically adjust and correct the print deposits based on the feedback given with regards to poor printing quality. This will facilitate improved print quality and production efficiency, by forming a complete printing feedback system.

Back to Back (BTB)

2 Machines back to back is a perfect match to all dual lane SMT lines. The machines can be operated independently of each other, running different types of product.

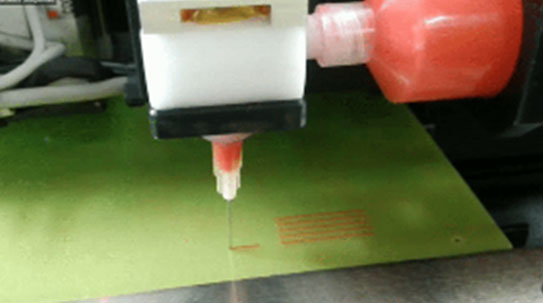

Auto Glue Dispensing

Attached on CCD camera XY axis, the dispenser provides basic function of glue dotting using syringe type dispensing needle after solder paste printing.

Machine in Series

With 2 printers in series, it doubles your output, providing you with reduced cycle time.