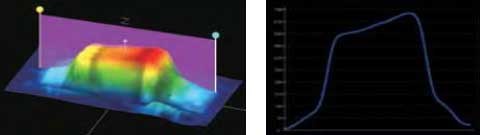

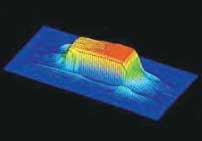

TRI's optimum 3D AOI solution delivers the fastest multi-angle PCB inspection coupled with blue-laserbased true 3D profile measurement for the highest automated optical defect symptoms coverage possible. Combining state-of-the-art software solution and third generation intelligent hardware platform, the TR7500 SIII 3D offers robust 3D solder and component defect inspection and with high inspection coverage and easy programming.

AOI Key Features

Multi Angle Color Cameras

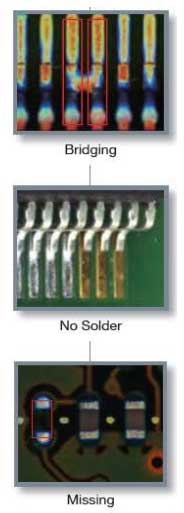

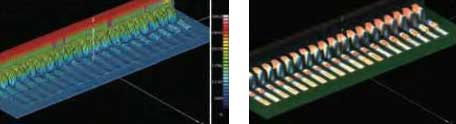

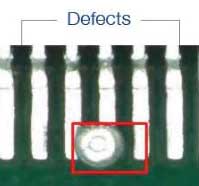

New generation color angle view cameras make side view inspection a breeze. Finding complex solder joint defects hidden from top view has never been easier, and new color space processing ensures reliable defect detection.

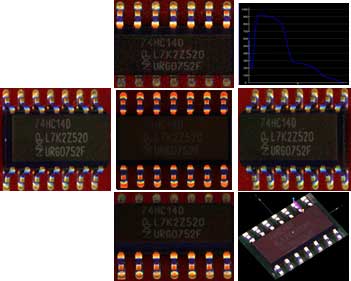

IC Lead Inspection Using 2D + 3D Technologies Efficiently Reveals Lifted Leads

3D Chip Inspection Reveals Defects on Both Small and Oversized Components

Complete Inspection Coverage from TR7500 SIII + 3D

Extra Components

Lifted Components