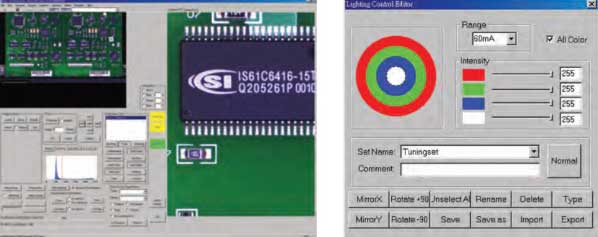

Equipped with a 1-CCD high resolution color camera, the TR7502 DT desktop automated optical inspection system offers TRI' trademark Dynamic Imaging technology for powerful pre/post reflow inspection in a compact economical solution. The system features a highly flexible coaxial RGB+W lighting system with low-angle lighting for better inspection of polarity and black components and is capable of inspecting 01005 fine pitch components in both lead-free and legacy PCB assemblies.

AOI Key Features

Easy Programming Environment

Built-in Model Library Function