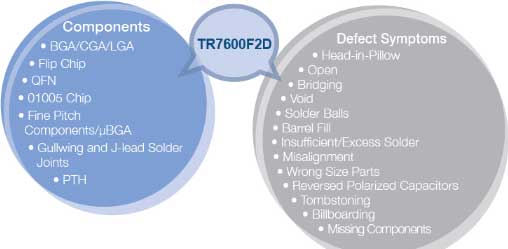

TR7600F2D is a high performance inline 2.5D AXI specialized for single layer PCB and FPCB assemblies requiring highest image quality. Ideal for mobile electronics applications, the TR7600F2D can reliably detect microscopic voids, 01005 solder defects, and many QFN and BGA problems. Combining a fully automated programming and multi-resolution programs help maximize production yields on any production line.

AXI Key Features

Defect Detection Capability

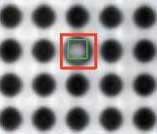

BGA Head in Pillow

BGA Void

Bridging

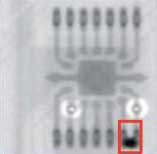

QFN Open

Press Fit Pin Defect

Solder Ball