The TR7700Q Automated Optical Inspection combines the latest of 2d and 3D technologies based on digital quad pattern projection to revolutionize PCB assembley inspection.

3D Automated Optical Inspection

TR7700Q Features

Maximum precision with 4-way Projection

TR7700Q combines a high resolution orthogonal camera and quad multi-angle digital fringe pattern projection for best inspection coverage.

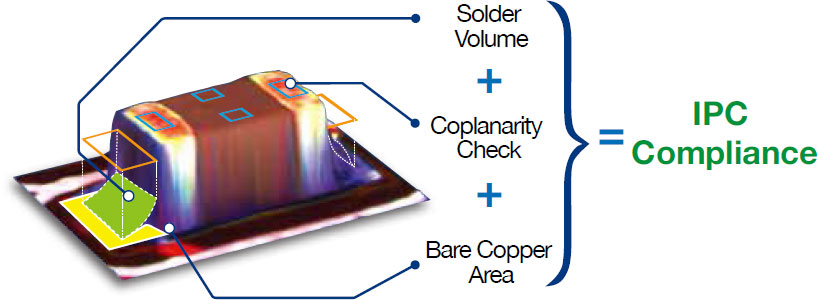

Three-Strategy Solder Inspection

TR7700Q analyzes several solder joint parameters to locate non-compliant soldering defects.

Complete 3D PCB Assembly Inspection

TR7700Q ensures all visible solder joints meet IPC specifications or your chosen criteria.

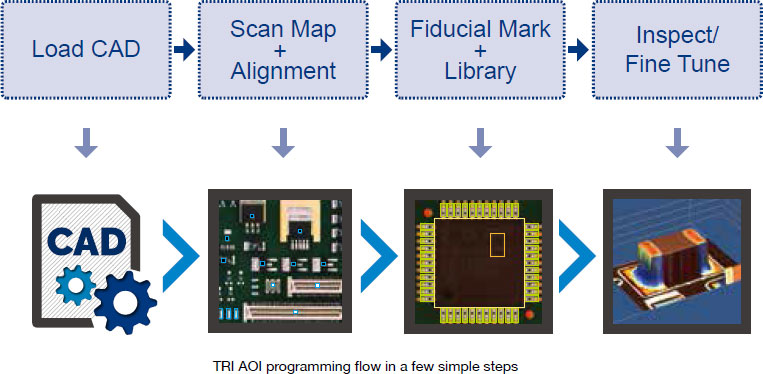

From CAD to Inspection in Minutes

TRI's Intuitive software and smart component libraries streamline new product introduction in a few simple steps.

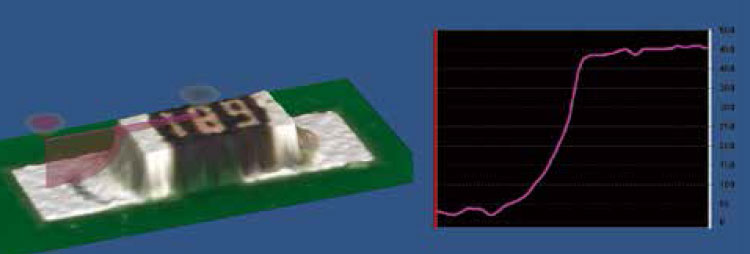

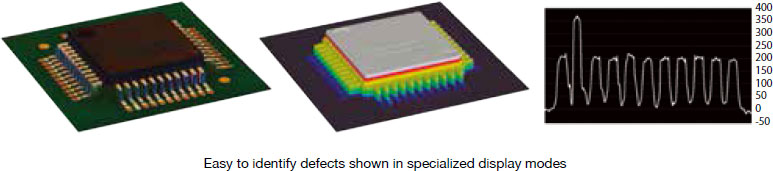

Intuitive Inspection Results

Reviewing defects on TR7700Q is a breeze with intuitive profile visualization.

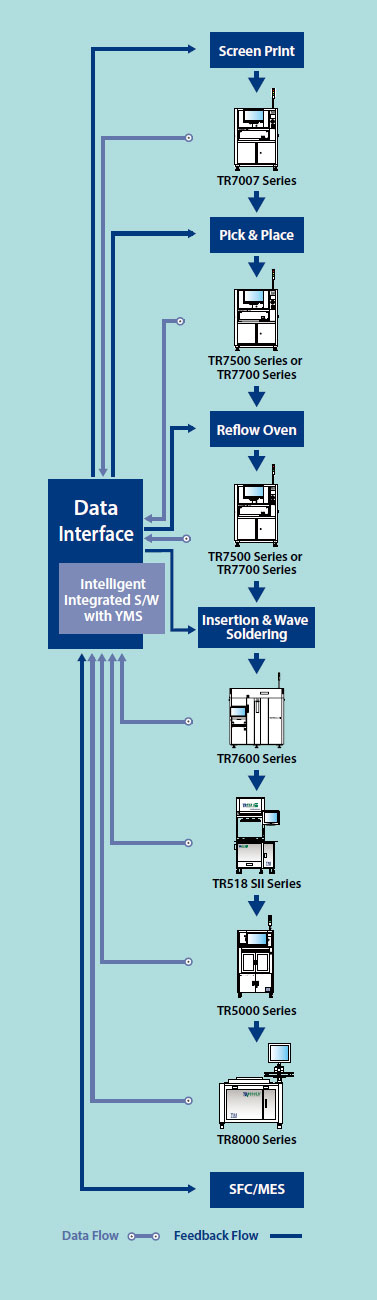

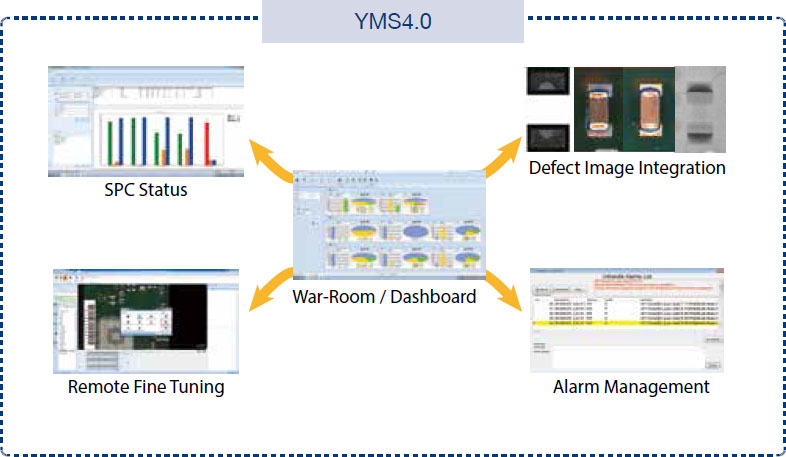

Industry 4.0 Production Line Integration

YMS 4.0 lets TRI inspection solutions interface and share inspection data with the shop floor system and other inspection machines. With the central console an operator can control, track, analyze and optimize the inspection process across the entire production line and obtain real actionable data to optimize production quality in the Industry 4.0 environment.

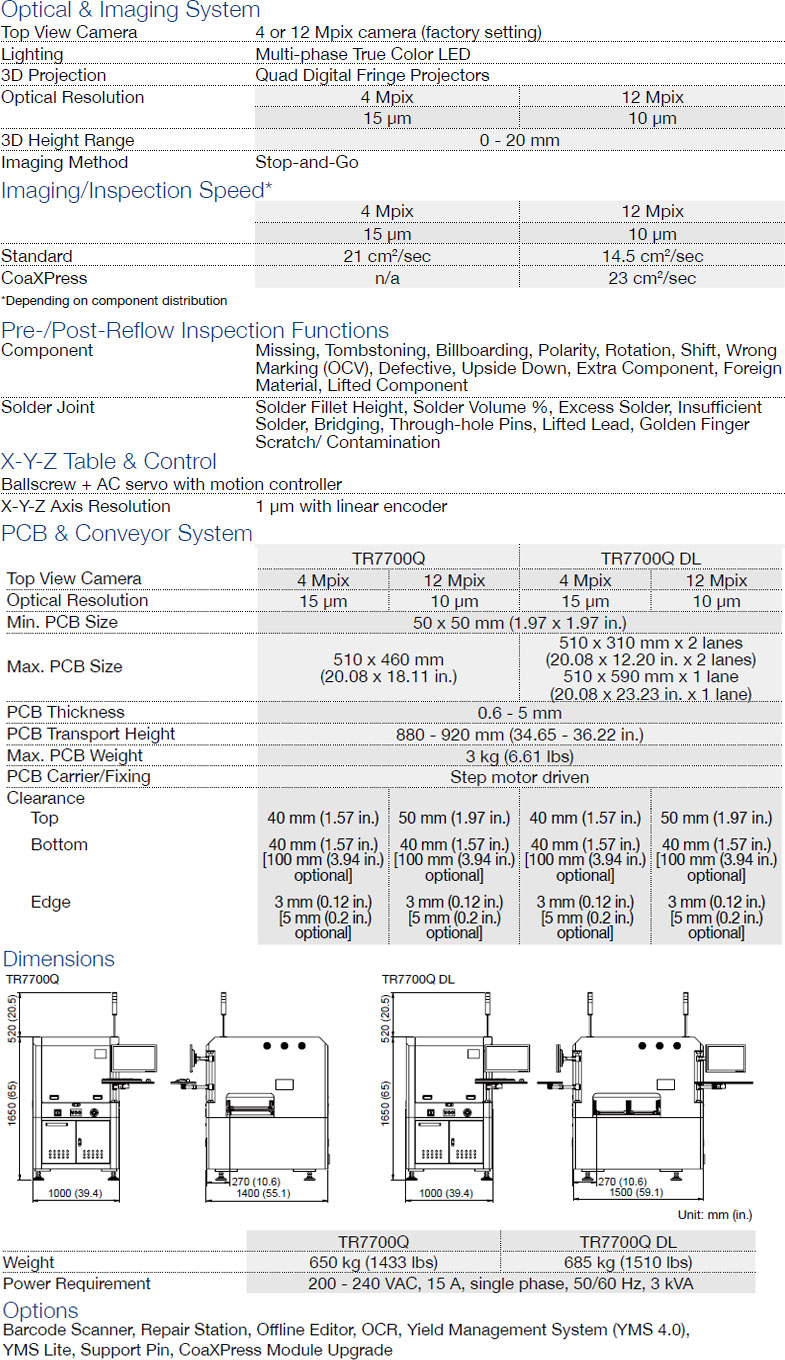

Specifications

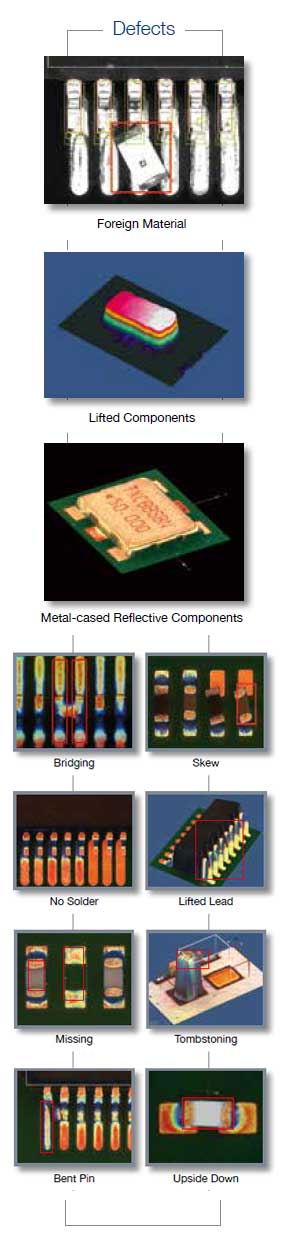

Extra Components

Lifted Components